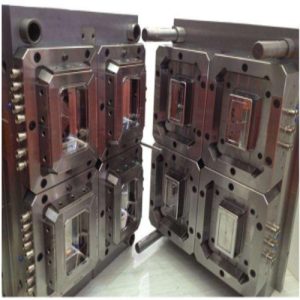

Custom Molding Tools

At Thriarr Polymers Pvt. Ltd., we specialise in the design and manufacture of custom moulding tools tailored to meet the specific requirements of our clients. Our expertise ensures the production of high-quality, precision-engineered components across various industries, including electrical, automotive, and energy sectors.

Our Custom Moulding Tool Services

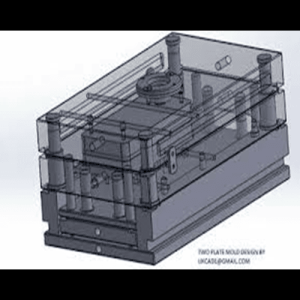

Tool Design and Engineering: Our experienced engineers collaborate closely with clients to develop detailed designs that align with product specifications and manufacturing requirements. We utilise advanced Computer-Aided Design (CAD) software to create accurate models, facilitating efficient production processes.

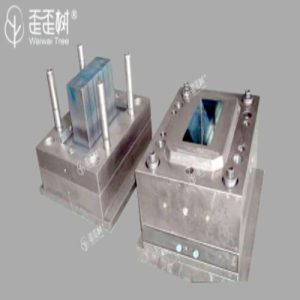

Prototype Development: We offer prototype tooling services to validate designs before full-scale production. This approach allows for testing and refinement, ensuring that the final product meets all functional and quality standards.

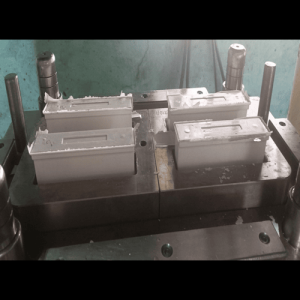

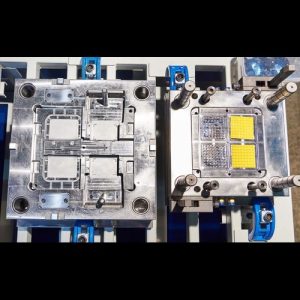

Tool Fabrication: Utilising high-quality materials such as special steel for the core and cavity. Toughened steel is used for the mould base. We fabricate durable and precise moulds with the help of CAM-operated machines, capable of withstanding the demands of high-volume production. Our in-house tool shop enables us to produce over 350 new tools annually, ensuring quick turnaround times for our clients.

Mold Sampling and Process Development: We provide comprehensive mould sampling and process development services, including injection moulding of thermoplastic, elastomeric, and liquid silicone rubber (LSR) components. Our team offers tailored tooling trial, sampling, and inspection/validation solutions to meet specific project needs.

Benefits of Our Custom Moulding Tools

Precision and Accuracy: Our custom moulds are engineered to produce components with tight tolerances, ensuring consistency and high-quality standards in every part.

Cost Efficiency: While the initial investment in custom tooling may be higher, it leads to significant cost savings over time due to reduced production errors, lower scrap rates, and the ability to produce complex parts without additional tooling.

Flexibility: We design moulds that accommodate a wide range of product specifications, enabling manufacturers to produce a diverse array of products.

Quality Control: Custom tooling helps ensure that final products meet specific quality standards, such as consistent wall thickness, uniformity in colour and texture, and dimensional accuracy.

Our Process

Consultation: We begin by understanding your specific requirements, including product design, material selection, and production volume.

Design: Our engineers create detailed CAD models of the proposed mould, considering factors such as part geometry, material flow, and cooling channels.

Prototyping: We develop prototype moulds to test and validate the design, making necessary adjustments to optimise performance.

Fabrication: Once the design is finalised, we proceed with the fabrication of the production mould, ensuring it meets all specified requirements.

Testing and Validation: We conduct thorough testing to ensure the mould produces parts that meet quality and performance standards.

Production Support: We provide ongoing support during the production phase, including maintenance and modifications to the mould as needed.

Industries Served

Electrical: Manufacturing components such as switchgear parts, connectors, and insulators.

Automotive: Producing parts like engine components, interior fittings, and electrical connectors.

Energy: Creating components for renewable energy systems, including wind turbine parts and solar panel connectors.

Quality Assurance

We adhere to ISO 9001:2015 standards, ensuring that every mould and component meets stringent quality and reliability criteria. Our commitment to quality is reflected in our rigorous testing and inspection processes at each stage of production.

Customisation

Understanding that each client has unique requirements, we offer tailored solutions to meet specific needs, ensuring optimal performance and satisfaction.